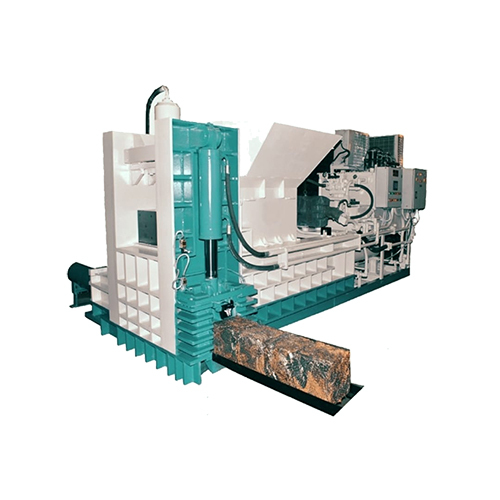

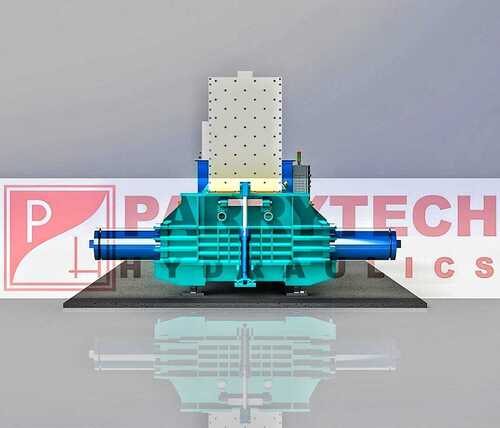

Continuous Balling Machine

5000000.00 INR/Piece

Product Details:

- Color COMPANY STANDARD

- Usage Industrial

- Product Type HYDRAULICS MACHINE

- Weight 15000-16000 Kilograms (kg)

- Power Source Hydraulic

- Condition New

- Power(W) 75 Horsepower (HP)

- Click to View more

X

Continuous Balling Machine Price And Quantity

- 1 Piece

- 5000000.00 INR/Piece

Continuous Balling Machine Product Specifications

- Industrial

- New

- HYDRAULICS MACHINE

- 15000-16000 Kilograms (kg)

- 75 HP

- Hydraulic

- 75 Horsepower (HP)

- PLC AUTOMATIC

- COMPANY STANDARD

Continuous Balling Machine Trade Information

- 5 Piece Per Month

- Months

- NORMAL

- Australia North America South America Eastern Europe Western Europe Middle East Africa Central America Asia

- All India

- yes company is certify with ISO 9001-2015

Product Description

A continuous balling machine is a type of machine used to form uniform-sized balls or pellets from a variety of materials, such as iron ore, coal, and other mineral concentrates. The machine uses a combination of pressure and rolling action to create the balls, which are then dried and hardened through a process known as induration. The continuous balling machine is typically used in the mining and metallurgical industries, where it is used to create pellets or balls from raw materials that are then used in the production of steel and other metal products. The machine works by feeding the raw material into a rotating drum or pan, which contains a series of discs or rollers that press and roll the material into the desired shape.

The benefits of using a continuous balling machine include the ability to produce high-quality balls or pellets at a consistent rate, which can improve the efficiency of the production process. Additionally, the machine can help to reduce waste and improve the overall yield of the process, leading to cost savings for the manufacturer.

There are different types of continuous balling machines available, including disc pelletizers, drum pelletizers, and balling drums. The choice of machine depends on the specific requirements of the application and the characteristics of the raw materials being used. In summary, a continuous balling machine is a critical piece of equipment in the mining and metallurgical industries, used to create uniform-sized balls or pellets from raw materials that are then used in the production of steel and other metal products. The machine offers numerous benefits, including improved efficiency, reduced waste, and cost savings for the manufacturer.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Baling Press' category

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free