Showroom

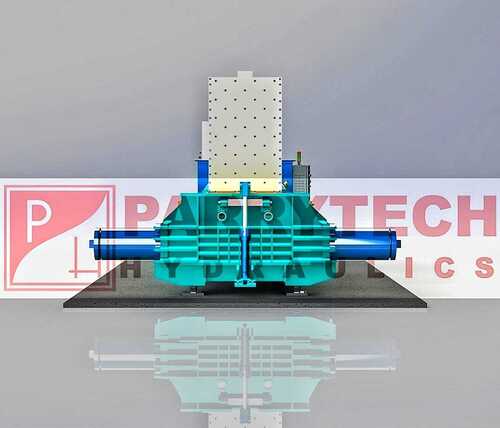

Hydraulic Bailing Press machines are automatic in function and have strong and sturdy construction body frame. These are provided with different speed control buttons and have triple action hydraulic system.

This array of 3 phase Kitchen Sink Making Machineries is known for its high automation degree. These mild steel made hydraulic systems have PLC controlled mechanism. These consume 40 amp power and their weight is 18 ton.

Hydraulic Rubber Moulding Press are widely used to make varied products in different sectors such as thermoset plastic, bakelite, thin metal, foam, resin, and building materials forming to name a few.

Hydraulic Press machines are equipped with computerized panel, powerful motor, transmission and sliding block & are sturdy in construction. These are reliable in performance, corrosion resistance and modern in design.

Hydraulic Deep Drawing Presses are used for developing metal sheets. Its operating principle is based on Pascals law. As part of its operation, it uses hydraulic cylinder for producing compressive force.

Offered range of Cooking Hob Drawing Machines can be availed in manual, semi automatic and automatic operating mode based choices. These systems can deliver 10 strokes in each minute. These are equipped with pump, valve, oil seal, bed etc.

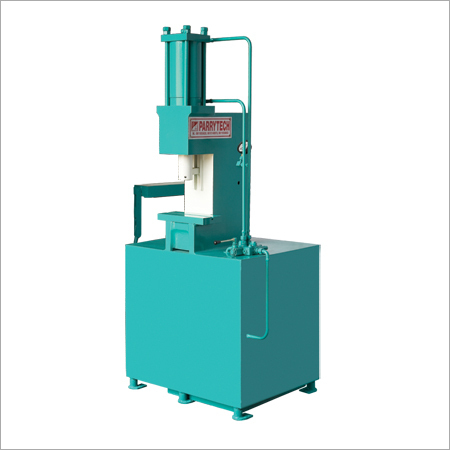

Hydraulic Moulding Press machines are designed with vertical and compact shape. The industrial machines have higher pressure function to uniformly fill the mold cavity with reinforcing fiber in seamless finishing.

This range of semi automatic Hydraulic Shearing Machines adopts NC or CNC controlled mechanism. Motor power of these systems ranges between 1 hp to 100 hp and these need 220v voltage to operate.

Known for their PLC controlled mechanism, this range of Lpg Cylinder Plants is known for its hydraulic driving method and PLC controlled mechanism. Low production charge, user friendly operating interface and long service life are their main aspects.

This array of Hydraulic Deep Draw Presses has been developed by using quality approved raw materials. These machines have long working life and low production cost. Maximum operating pressure of these systems is 210 bar.

Press Brake Machines have digital display which helps provide easy and quick results as well as great efficiency in working. These are used for upper transmission operation with mechanical limit stopper.

Hydraulic Cutting Machines are constructed with left and right wall boards which provide high accuracy, strength and durable quality. These are strong and sturdy as well as corrosion resistance.

Stamping machines are equipped with inner balance structure, adjustable heating temperature properties and computerized panel board. These are provided in varied styles, sizes and designs with modern technology.

Mild steel manufactured Hot Moulding Press machines are qualitative in manner. These are simple in handling, require less maintenance, corrosion resistance and have long lasting life. The machines have high speed working intensity.

Bending Machines are used for stamping and smoothing the surface of metal products. These are semi-automatic in function, tensile in strength, sturdy construction and have long lasting life.

These single or double acting Hydraulic Cylinders can be availed in 1000 ton capacity. These can endure up to 250 bar operating pressure and these are accessible in customized specifications. These require 220v voltage and their maximum motor power is 100 hp.

This range of semi-automatic Hydraulic Power Packs is accessible with 1 hp to 100 hp motor power range. These electric or hydraulic systems can be availed in customized design. Maximum voltage needs of these systems is 220v.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free